The Major Types Of Encapsulating And Potting Compounds For PCB

The Major Types Of Encapsulating And Potting Compounds For PCB

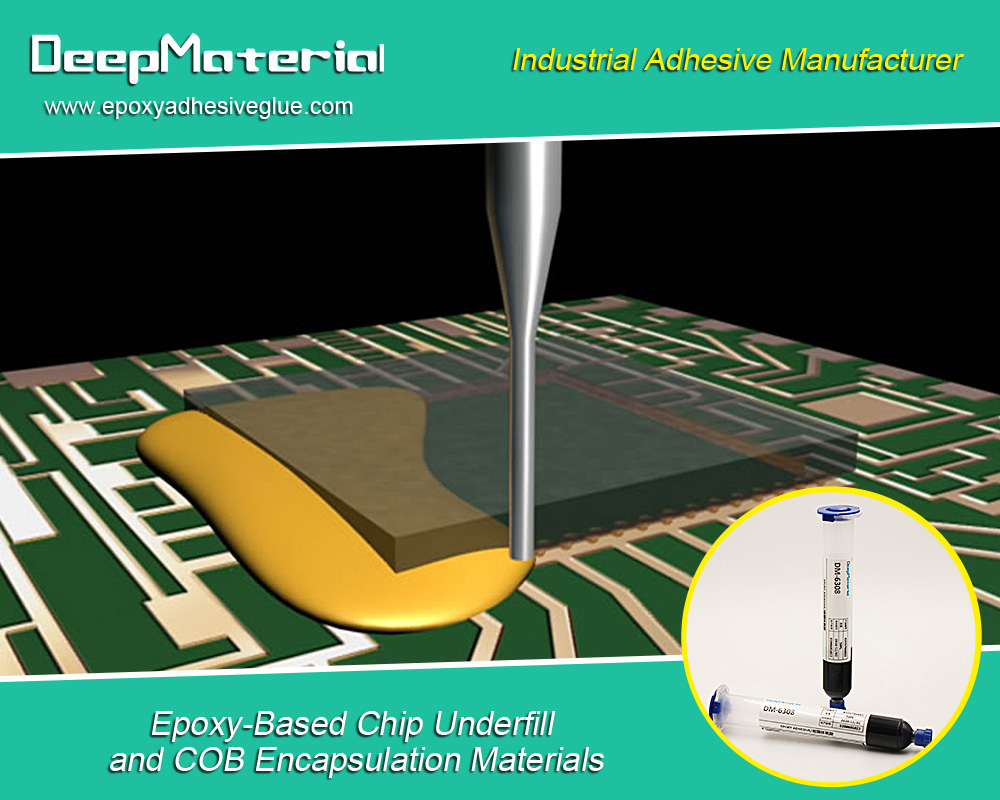

Printed circuit boards are very important parts of electronics. They act as the brain for most and should therefore be safeguarded as much as possible from all harmful elements. Potting is among the methods used to offer much-needed protection for the boards or substrates. The process is done by filling the PCB housing with the most suitable liquid compound. The compound is left to cure before fully protecting the important electronic parts.

Apart from the housing, the filling can cover the entire board and components. It can also be done on specific components depending on the needs. This is an excellent method of keeping abrasion, heat, chemical, and environmental damages at bay. Different materials are used as potting compounds for PCB, and the major ones are silicone, epoxy, and polyurethane.

- Epoxy

This PCB potting material is commonly loved for its durability and chemical resistance. It also offers high adhesion bound to last for a very long time. However, the material takes a long to cure and needs time to set.

- Polyurethane

As a potting material, polyurethane is softer compared to epoxy. It makes a good choice for sensitive connectors and electronic components which cannot tolerate rigid materials like epoxy. However, the heat and moisture resistance of this potting compound is not as strong.

- Silicone

Silicone is loved for its flexibility and durability. It is probably the most popular potting material today because it suits most applications and can withstand extreme temperatures. The only challenge is that it can be costly, making it impractical in some applications.

Is potting necessary?

Potting offers an easy and fast way of offering protection to all applications. It is easy to apply in high-volume productions and assembly lines. Compared with thin conformal coatings, potting offers thicker coats that are resilient and durable. By potting your PCB, you give them:

- High resistance to chemicals, environmental hazards, vibrations, and heat

- Increased durability, especially against abrasions and impacts

- Additional design security, especially when you go for dark-colored compounds

- Greater protection against electrical arcs and water damage

Potted devices, however, can be challenging to rework because removing the potting could end up destroying the circuit board. Compared to devices coated with conformal materials, they are more challenging to work with. Potting also comes with other disadvantages, including:

- Inflexibility

- High costs

- Significant weight increase on the PCBs

- Additional processing steps

But even with the challenges, the potting material you choose for your components will often determine the kind of experience you get. And with the several options, you will always find a suitable material for your application needs. The potting compounds offer the same benefits across the board, but the brand you choose can determine the quality you get.

The best you can do for your circuit boards is choose products you can fully trust or quality. Products from Deep Material are some of the best in the market as far as quality goes. The best thing about the company is it has a wide range of products and finding what suits your needs is easy. Better still, you can have a special product formulated to suit your needs.

For more about the major types of encapsulating and potting compounds for pcb,you can pay a visit to DeepMaterial at https://www.epoxyadhesiveglue.com/epoxy-potting-compound-for-pcb-the-options-and-benefits/ for more info.