The Benefits of Using 2 Part Structural Adhesive for Industrial Applications

The Benefits of Using 2 Part Structural Adhesive for Industrial Applications

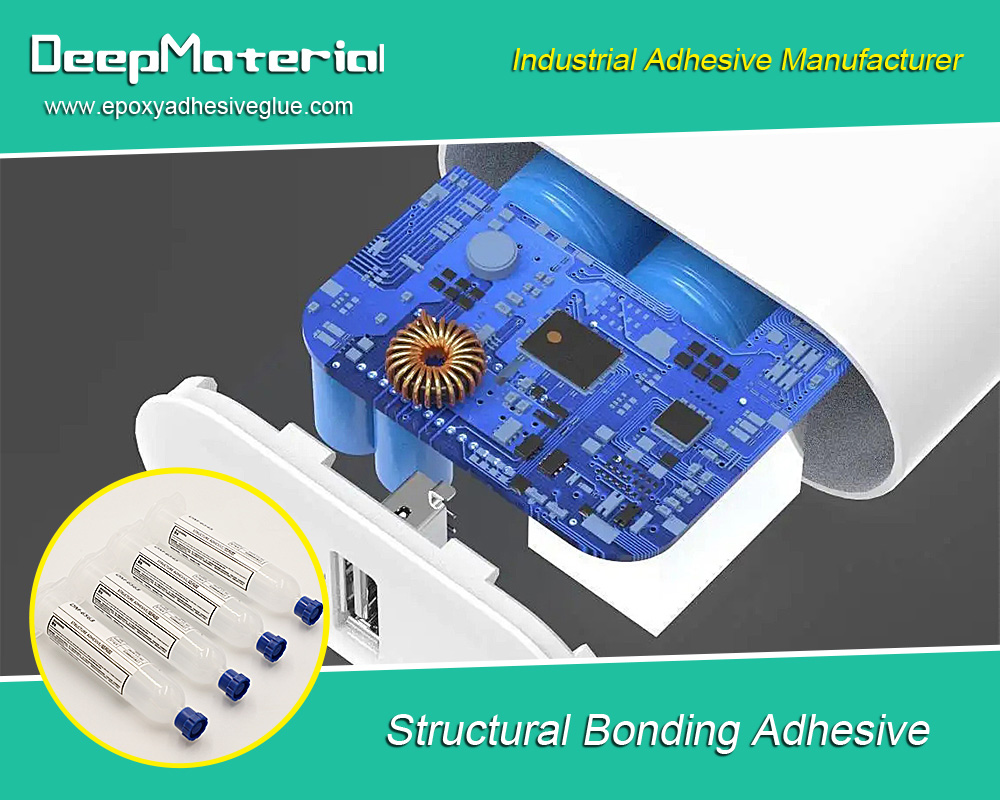

In industrial applications, bonding is a crucial process that ensures the durability and longevity of materials. One of the most effective bonding solutions available today is the 2 Part Structural Adhesive. This type of adhesive is designed to create a strong and long-lasting bond between two materials. Today, we will explore the advantages of using 2 Part Structural Adhesive in industrial applications.

Stronger Bonding Capabilities of 2 Part Structural Adhesive

The 2 Part Structural Adhesive is a two-component adhesive that consists of a resin and a hardener. When these two components are mixed together, a chemical reaction occurs, creating a strong and durable bond between the materials being bonded. This chemical reaction is what sets 2 Part Structural Adhesive apart from other types of adhesives.

Compared to other types of adhesives, such as cyanoacrylate or epoxy, 2 Part Structural Adhesive has a much stronger bonding capability. This makes it ideal for use in industries that require a high level of bonding strength, such as aerospace, automotive, and construction.

Increased Durability and Longevity of Bonded Materials

The strong bonding capabilities of 2 Part Structural Adhesive also result in increased durability and longevity of the materials being bonded. This is because the adhesive creates a bond that is resistant to impact, vibration, and other external factors that can cause materials to break apart.

Materials that benefit from increased durability and longevity include metals, plastics, and composites. In the aerospace industry, for example, 2 Part Structural Adhesive is used to bond aircraft components together, ensuring that they can withstand the stresses of flight.

Enhanced Resistance to Environmental Factors

Another advantage of 2 Part Structural Adhesive is its enhanced resistance to environmental factors such as moisture, heat, and chemicals. This makes it ideal for use in industries that operate in harsh environments, such as marine, oil and gas, and chemical processing.

The adhesive’s resistance to moisture, for example, makes it ideal for bonding materials that will be exposed to water, such as boats and offshore structures. Its resistance to chemicals makes it ideal for use in chemical processing plants, where materials are exposed to corrosive substances.

Improved Flexibility and Versatility in Industrial Applications

2 Part Structural Adhesive is also highly versatile and is usually used in a wide range of industrial applications. For instance, it is used to bond a variety of materials, including plastics, metals, and composites. It can also be used in applications that require flexibility, such as bonding materials that will be subjected to vibration or movement.

Industries that benefit from improved flexibility and versatility include automotive, electronics, and medical devices. In the automotive industry, for example, 2 Part Structural Adhesive is used to bond body panels together, ensuring that they can withstand the stresses of driving.

Reduced Production Time and Costs

Using 2 Part Structural Adhesive can also help to reduce production time and costs. This is because the adhesive cures quickly, allowing for faster production times. It also eliminates the need for mechanical fasteners, such as screws or bolts, which can be time-consuming to install.

Industries that benefit from reduced production time and costs include manufacturing, construction, and electronics. In the construction industry, for example, 2 Part Structural Adhesive is used to bond building materials together, reducing the need for mechanical fasteners and speeding up construction times.

Enhanced Safety and Health Benefits for Workers

2 Part Structural Adhesive also offers enhanced safety and health benefits for workers. Unlike other types of adhesives, such as solvent-based adhesives, 2 Part Structural Adhesive does not emit harmful fumes or require special ventilation systems. This makes it safer for workers to use and reduces the risk of health problems associated with exposure to harmful chemicals.

Industries that benefit from enhanced safety and health benefits include manufacturing, automotive, and construction. In the automotive industry, for example, 2 Part Structural Adhesive is used to bond car components together, reducing the risk of injury to workers who would otherwise have to use mechanical fasteners.

Improved Aesthetics and Appearance of Bonded Materials

In addition to its functional benefits, 2 Part Structural Adhesive can also enhance the overall look of bonded materials. This is particularly important in industries such as automotive and aerospace, where appearance is a crucial factor in the success of a product. By creating a seamless bond that is invisible to the naked eye, 2 Part Structural Adhesive eliminates the need for unsightly mechanical fasteners that can detract from the visual appeal of a finished product.

This adhesive is used on various materials, including metals, plastics, as well as composites. Such makes it a flexible solution for many different applications. Additionally, because it does not damage the surface of materials, it can be used on delicate or sensitive surfaces without causing any harm. Overall, 2 Part Structural Adhesive is an excellent choice for anyone looking to improve both the functionality and appearance of their bonded materials.

Industries that benefit from improved aesthetics and appearance include furniture, electronics, and consumer goods. In the furniture industry, for example, 2 Part Structural Adhesive is used to bond wood and other materials together, creating a seamless and attractive finish.

Increased Productivity and Efficiency in Industrial Processes

Using 2 Part Structural Adhesive can also increase productivity and efficiency in industrial processes. This is because the adhesive can be applied quickly and easily, without the need for special tools or equipment. It also eliminates the need for additional finishing processes, such as sanding or painting.

Industries that benefit from increased productivity and efficiency include manufacturing, construction, and electronics. In the electronics industry, for example, 2 Part Structural Adhesive is used to bond components together, reducing the need for additional finishing processes and speeding up production times.

Final Thoughts

In conclusion, 2 Part Structural Adhesive offers a wide range of advantages for industrial applications. Its strong bonding capabilities, increased durability and longevity, enhanced resistance to environmental factors, improved flexibility and versatility, reduced production time and costs, enhanced safety and health benefits, improved aesthetics and appearance, and increased productivity and efficiency make it an ideal choice for a variety of industries.

By using 2 Part Structural Adhesive, industries can improve the quality and durability of their products, reduce production times and costs, and enhance the safety and health of their workers. As such, it is an essential tool for any industry that requires a high level of bonding strength and durability.

For more about choosing the Structural Adhesive for Industrial Applications,you can pay a visit to DeepMaterial at https://www.epoxyadhesiveglue.com/category/epoxy-adhesives-glue/ for more info.