Seamless Solutions: Exploring Adhesives for Home Appliances

Seamless Solutions: Exploring Adhesives for Home Appliances

The transformative impact of adhesives on 21st-century home appliances is a well-established fact. These remarkable compounds are reshaping the very foundations of design, manufacturing, and functionality within this industry.

By bolstering structural robustness and achieving a flawlessly streamlined appearance, adhesives are unmistakably guiding these appliances towards a novel trajectory. Consequently, the landscape of everyday appliances, fundamental to our routine tasks, has been significantly molded by this innovative direction.

In this post, we will explore the ways in which this emerging wave of adhesive solutions is fostering qualities of grace, longevity, and effectiveness within the diverse confines of our households.

Importance of Adhesives in Modern Home Appliances

In the realm of contemporary home appliances, adhesives assume a substantial role. They have revolutionized manufacturing methods and design approaches, consequently impacting overall functionality. Notably, adhesives tailored for home appliances contribute to heightened structural robustness, refined performance, and the achievement of flawlessly smooth aesthetics.

A multitude of contemporary advancements owe their existence to the integration of adhesives within the home appliance industry. These adhesive solutions contribute to durability assurance, vibration reduction, and the provision of material versatility, all playing pivotal roles in facilitating innovation.

Evidently, as time progresses, home appliances are poised to become increasingly compact and visually captivating. In this evolving landscape, adhesives are set to play a pivotal role, actively contributing to driving this transformative shift.

The History of Adhesives for Home Appliances

Adhesives for home appliance has come a long way. Initially, the assembly of home appliances relied on conventional bonding techniques. However, this shifted from mechanical fastening to adhesive bonding during the mid-20th century. Predictably, this transition was accompanied by numerous challenges and constraints within the industry.

The evolutionary journey of adhesives for home appliances offers captivating insights. Subsequently, we entered an era characterized by tailored adhesive solutions designed for specific home appliances. This evolution led to the development of adhesive formulations adept at adapting to variations in load, temperature, and moisture.

Novel bonding techniques emerged to address intricate and diverse component requirements. This progression fostered increased collaboration between appliance designers and adhesive manufacturers, signifying a harmonious synergy of innovation.

How Adhesives Can Enhance Structural Integrity

As previously highlighted, the significance of adhesives in contemporary home appliances cannot be overstated. A critical role they assume is the enhancement of structural integrity. Within home appliances, adhesives are employed to alleviate stress and ensure enduring joints.

The application of adhesives in home appliances contributes to an extended lifespan, effectively diminishing the prospects of wear and tear. Furthermore, they act as a safeguard, minimizing potential safety hazards by curbing the occurrence of structural failures.

A notable advantage brought about by adhesive solutions in home appliances is the facilitation of space-efficient designs. This innovation in bonding agents has substantially influenced structural integrity, bolstering both reliability and longevity in the realm of home appliance applications.

The Impacts of Adhesives on Aesthetics

The aesthetics of modern home appliances have undergone remarkable transformations, courtesy of cutting-edge adhesive solutions. Adhesives have evolved beyond their conventional role as mere bonding agents, now serving as integral components that elevate the visual appeal of these appliances.

With the advent of new adhesive technologies, manufacturers are embracing streamlined approaches to appliance production. The once prevalent use of conventional fasteners like screws and bolts is gradually fading, as adhesives contribute to a more captivating appliance appearance. This shift has resulted in home appliances exuding heightened presentation and sophistication, largely attributed to adhesive integration.

Furthermore, manufacturers now enjoy the creative freedom to explore diverse shapes and materials previously hindered by traditional bonding methods. This newfound flexibility has ushered in a wave of industry innovations, leading to the emergence of captivating and enchanting appliance designs.

The impact of adhesives on aesthetics within the home appliances sector is profound. Users have developed deeper emotional connections to modern appliances due to the sleekness achieved through contemporary adhesive solutions. These adhesive-driven enhancements not only enhance user experiences but also bolster visual allure.

Predictive data indicates a growing consumer demand for sleek and modern designs in the foreseeable future. Empowered by advanced adhesive solutions, manufacturers are poised to meet these demands confidently, delivering appliances that seamlessly align with evolving aesthetic preferences.

Challenges Experienced in The Home Appliances Industry

The integration of adhesives into home appliances has met with stiff challenges of various dimensions. Some of the challenges experienced are;

- Environment and Temperature – Adhesives are expected to perform optimally across a range of temperatures. Their operations are also guarded against chemical, humidity, and moisture changes.

- Compatibility – There must be compatibility between the different adhesive solutions and materials for reliability to be achieved.

- Production Speed – While fast curing is sacrosanct in this industry, the quality of assembly should not be sacrificed.

- Bond Strength – The need to achieve durability and consistency in bond strength across a variety of load conditions and surfaces.

- Design Limitations – The use of adhesive solutions that will not bring about design limitations.

Innovations That Address the Above Challenges

Manufacturers employ several measures to help address the above challenges. Some of the steps taken to ensure effectiveness and efficiency of adhesive solutions include;

- Surface Treatments – The use of primers to make surfaces more adhesive-friendly has become common place in the home appliance industry.

- Special Formulations – Special adhesive solutions are being formulated to enhance chemical resilience, durability, and temperature resistance for certain applications.

- Quick Curing – Quick curing adhesives that do not compromise bonding quality have become necessary in the assembly of home appliances today.

- Structural Adhesive Solutions – Production of high-quality structural adhesives that ensure flexibility and high bond strength.

Continual innovation within adhesive solutions is effectively tackling integration challenges, paving the way for enhanced performance, increased design flexibility, and elevated overall quality in contemporary home appliances.

Final Words

The home appliances industry owes a substantial portion of its evolution to cutting-edge adhesives. This post underscores the undeniable influence of adhesives on home appliances. This prevailing trend is headed in one direction: home appliances will be sleeker and even more visually appealing.

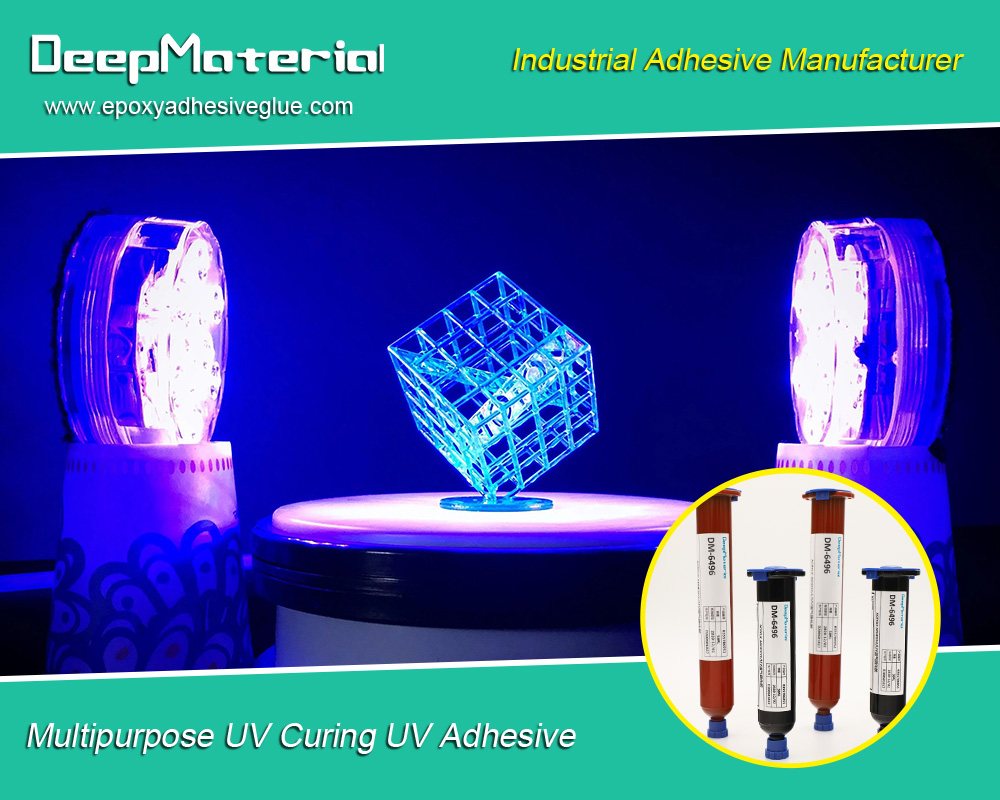

For more about choosing the exploring adhesives for home appliances, you can pay a visit to DeepMaterial at https://www.epoxyadhesiveglue.com/category/epoxy-adhesives-glue/ for more info.