Crafting the Future of Electronics: The Role of SMT Adhesive in Component Bonding

Crafting the Future of Electronics: The Role of SMT Adhesive in Component Bonding

SMT adhesives have continued to shape electronics into what it is today. Many of the innovations you see in the electronics industry today were possible due to the advent of surface mount technology adhesives. It can be said that electronics has become much smarter today because of this type of adhesive.

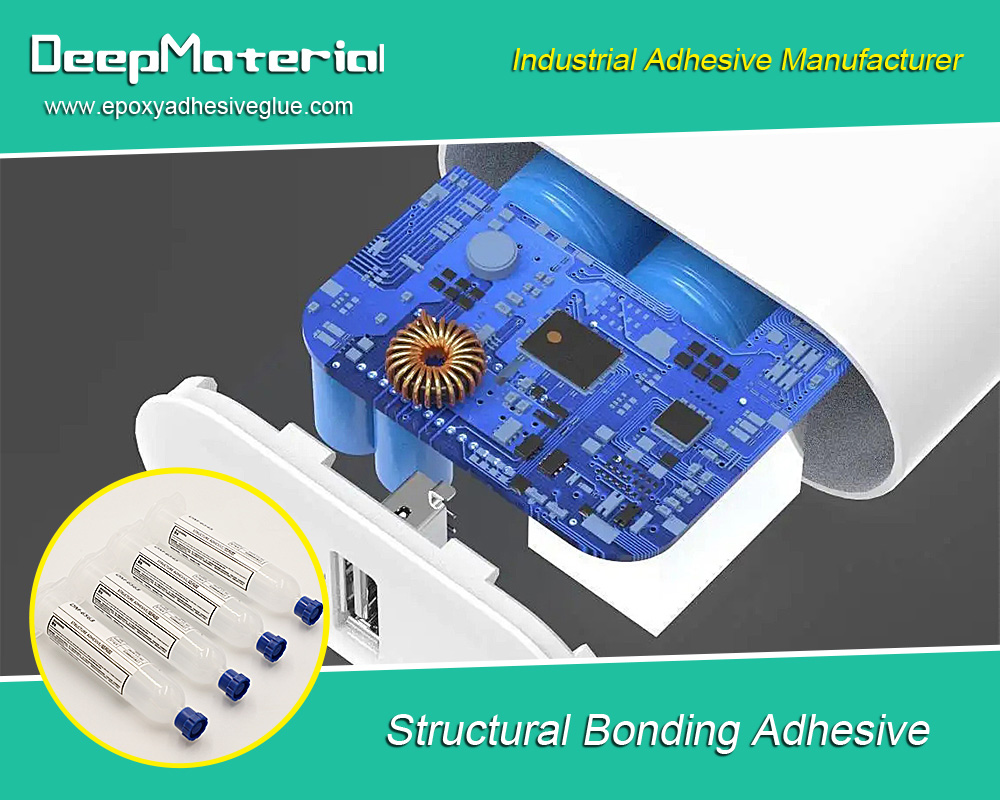

Electronic devices are usually composed of countless tiny components that are bonded securely to a PCB. SMT adhesive has proven to be extremely effective in bonding electronic components and ensuring they are properly connected.

Interestingly, there is more to SMT adhesives than just ensuring adhesion on electronics devices. Therefore, in this post, we will discuss how SMT adhesives continues to shape and redefine the state of electronics in 2023 and beyond.

The Basics of SMT Adhesives

Before delving into the role of SMT adhesive in component bonding, it is appropriate we understand the principle behind their operation. Understanding the nature and functionality of SMT adhesive will enable us to maximize their usage.

SMT is an acronym for surface mount technology. It is safe to consider SMT as the latest trend in electronic component bonding. SMT is different from the conventional method of bonding where components are bonded through holes. With SMT adhesives, electronic components can be glued directly on a PCB or printed circuit board.

The emergence and dominance of SMT has significantly impacted the electronics industry. Thanks to SMT adhesives, devices can be miniaturized more. Also, devices are lighter and more efficient because of this special adhesive.

SMT adhesive solutions are now in high demand because they are suited for high performance and compact electronics. As a result, SMT adhesives have become a household name in many industries, including telecommunications and consumer electronics.

SMT electronics components are the foundation of modern-day electronics. They are suitable for such electronics due to their small size and positioning. Some SMT components you may already know are capacitors, resistors, microcontrollers, and integrated circuits.

SMT components are more important in today’s electronics than you can imagine. For instance, they determine how electronic devices function and perform. SMT components also help to optimize space, ultimately reducing carbon footprints. Electronic devices perform better and last longer with SMT components.

Without any iota of doubt, it is obvious that electronic design and manufacture is moving in the direction of SMT. It is evident that researchers and manufacturers will stop at nothing to produce smaller, smarter, and more efficient devices.

Enhancing Electrical Performance

Electronics performance depends on their ability to conduct electricity and direct signal efficiently. So, any SMT adhesive used in this context is expected to do two things: ensure proper electrical conductivity for bonded electronics components and assure the complete transfer of signal between components.

A number of SMT adhesive properties can also influence how an electronic device will perform. Properties like conductivity, resistivity, and dielectric properties can affect how an electronic device performs. Therefore, these parameters should be considered before sticking with any SMT adhesive.

There are several factors that can affect the way electronics devices work these days. Interference ought to be reduced for electronics devices to perform optimally. Adhesive materials should not promote interference in such devices. The level of interference provided by any adhesive material should be reduced to the barest minimum for the device to work efficiently.

SMT adhesives reduce any potential interference because they define an appropriate path for the flow of electric signals.

In addition, SMT adhesives should be able to dissipate heat from an electronic device, contributing to stability and optimal performance.

SMT adhesive’s contribution in the electronics industry has been great. It has helped to ensure optimal performance and provided an enhanced mode of transmitting signals. This adhesive type has also contributed immensely in prolonging the durability of electronic components and ensuring they perform optimally for extended periods.

Ability to Demonstrate Resilience to External Elements

The use of electronics is subject to different temperatures. From temperate regions to extremely hot locations, electronics devices are used to do many things. So, if you are using any adhesive to bond electronics components, it should be one that can withstand the above temperature conditions. Thankfully, SMT adhesives are designed to survive the aforementioned temperatures.

SMT adhesives can remain the same even when devices are subject to temperature fluctuations. Most bond failures are caused by frequent expansions and contractions. However, an SMT adhesive can maintain its original bond structure when temperatures reach extreme levels.

Components bonded with SMT adhesives guarantee optimal performance even when they are taken to different environments and exposed to different conditions.

SMT adhesives also offer protection for electronics components. With such adhesives, electronic components are not affected by chemicals, dust, or moisture. SMT adhesives offer an extra layer of protection for electronics components from external elements.

The adhesives help electronics devices to last much longer because they shield the components from getting contaminated. The ability of electronic components to remain steadfast in the face of environmental challenges is key for optimal performance in all environments.

SMT adhesives have helped to shape the world of electronics by offering resilient features that can make electronics components survive unfavorable heat and environmental conditions.

Application Methods

SMT adhesives have various application methods. Different SMT bonding techniques are meant for specific electronic devices. The way an electronic component will be configured is what determines the method of bonding.

Some of the common bonding techniques include Stencil Printing, Dispensing, Jetting, Screen Printing, and Film Lamination.

An SMT adhesive should also be administered precisely to ensure accuracy and consistency in positioning. When the adhesives are properly applied, the bonds produced will last for a long time. It will also ensure the components are properly aligned to enable them function optimally.

Final Words

The benefits of SMT adhesives in the electronics industry cannot be overemphasized. They have contributed immensely in the transformation of electronics devices. SMT adhesive solutions are ideal for electronic components because they help to ensure durability and optimal performance.

For more about choosing the SMT adhesive in component bonding, you can pay a visit to DeepMaterial at https://www.epoxyadhesiveglue.com/category/epoxy-adhesives-glue/ for more info.